Methane CoGen System – District Energy at LOTT Building*

Case Study: Published | Updated: | | Olympia, Washington |- Category

- category_listing(s)

- Building Type

- Innovation

- Energy generation

- Jurisdiction

- Olympia, Washington

- Parcel

- Officials

- Tom Hill |

- Team

-

Tom Hill

|

approving-official

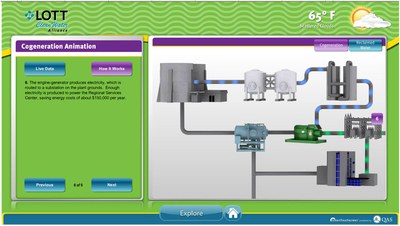

All of Thurston County, Tumwater, Olympia, and Lacey’s wastewater is cycled through the LOTT alliance. Methane is a natural bi-product of the entire water treatment process. This methane needs to be either used or disposed of, most companies doing the latter. The LOTT Alliance chose to recycle this methane using an innovative technology, the Co-Generation System that turns the methane into electricity. To permit this system, it first had to meet several key requirements.

One of the most important key success elements of the project was for the team of engineers to prove to Puget Sound Energy that the project was worthy. There was a lot of work. This was done in with plan and data review assistance, energy calculations, and funding support from Puget Sound Energy. A grant was secured from the PSE that would end up covering an impressive 70% of total costs for the project.

Due to the original 1984 Co-Gen system LOTT was already familiar with the permitting process for this type of project. However several permits required by the Department of Ecology required extra steps for approval, as did several Codes from the City of Olympia Building Code, and a stipulation enforced by PSE.

The methane co-gen project had to adhere to all the standing codes, however there are no code sections that specifically deal with methane co-gen systems. There are however, codes that define air quality and greenhouse gas emissions, which apply to this project.

All of the standard codes and permits had to be obtained for this project including the IMC, UPC, NEC, IBC

“Problem Codes” Determination of Non-significance under WAC 197-11-340(2).

This allowed them to by-pass obtaining an EIS (environmental Impact Statement) Though they did have to complete an Environmental Checklist approved by the Department of Ecology. This check list analyzed the future impact of the proposed methane Co-Generation project up-grade and determined no significant negative environmental effects. After all using the methane to power the generators does in effect reduce air pollution.

*It reduces air pollution by burning the methane by-product as fuel to create electricity, instead of simply flaring the gas off to dispose of it that way. Even so every new construction project of this caliber that is involved with the emissions of greenhouse gases (in this case CO2, methane) must comply the provisions of the Clean Air Act and obtain an ORCAA permit.

RCW Section/Title 70.94- 70.94.151

This Washington law outlines the requirements of the Clean Air Act adopted in 1968 . This is also the law that established ORCAA =Olympia Regional Clean Air Agency. This is the organizations that requires facilities like the LOTT Alliance which emit a higher amount of greenhouse gas than most buildings, to get an ORCAA permit before construction can begin. The ORCAA permit requires LOTT to test their emissions yearly, to ensure that the they do not surpass a certain amount of CO2, H2S, and siloxide, (methane ?) emissions.

nternational Building Code Chapter 27 Section 7

Emergency and Stand-by Power Systems

When LOTT asked to be hooked up to the grid PSE required that they meet this stipulation that would protect the rest of the power grid from receiving a power surge from the generators at LOTT if there where to be a large-scale grid failure. This code requires that LOTT have what is basically a massive breaker to stop electricity created by the generator from transferring into the grid if some type of massive failure was to happen in the Puget Sound Energy system at large.

Olympia Municipal Code Chapter 8.32 NOISE

This code applies to the sound ordinances that the LOTT facility to had to adhere to the stipulation listed there in. They had little trouble meeting the requirements, but it was a concern for the community.